And for such, it requires hands-on training and experience to carry out the process to fruition.

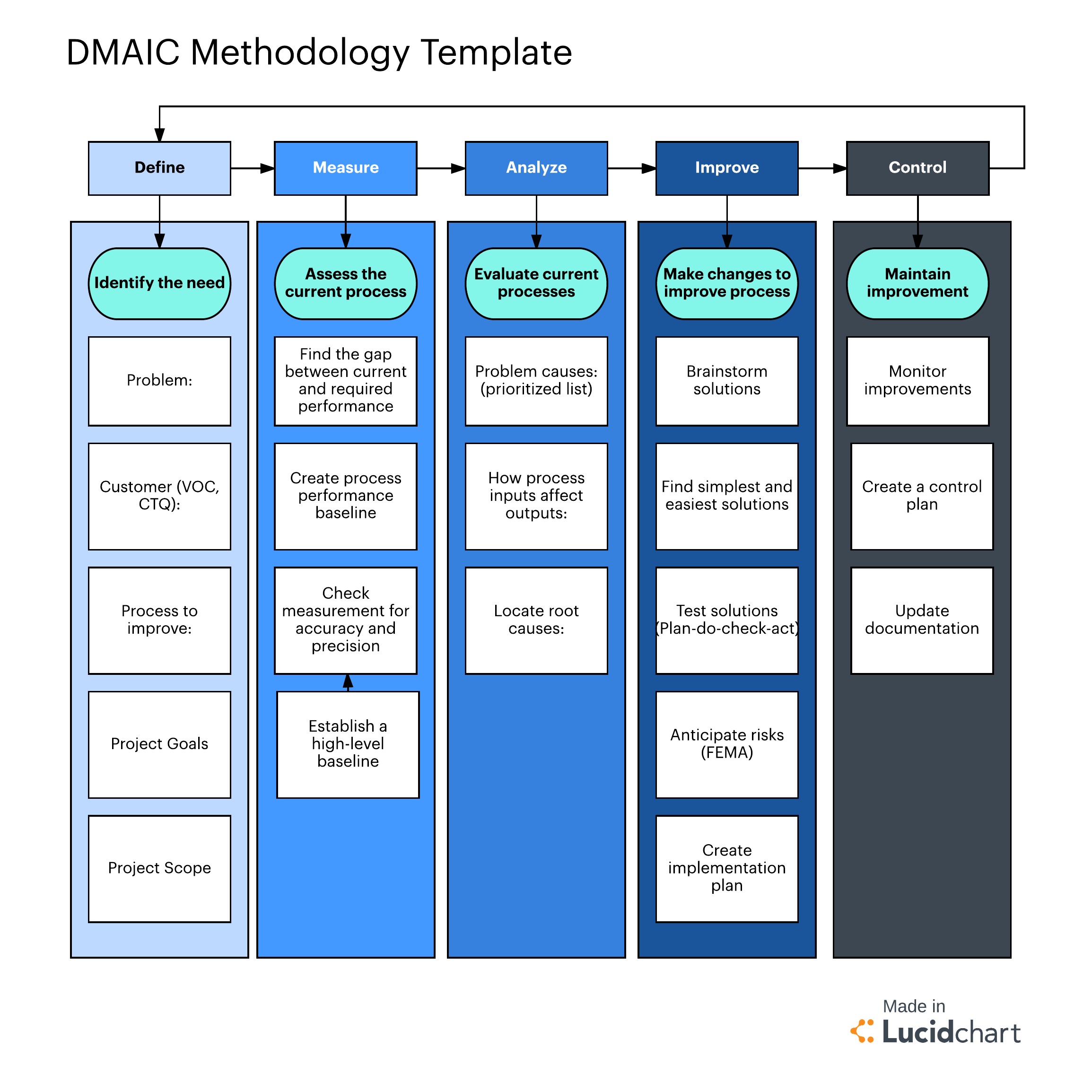

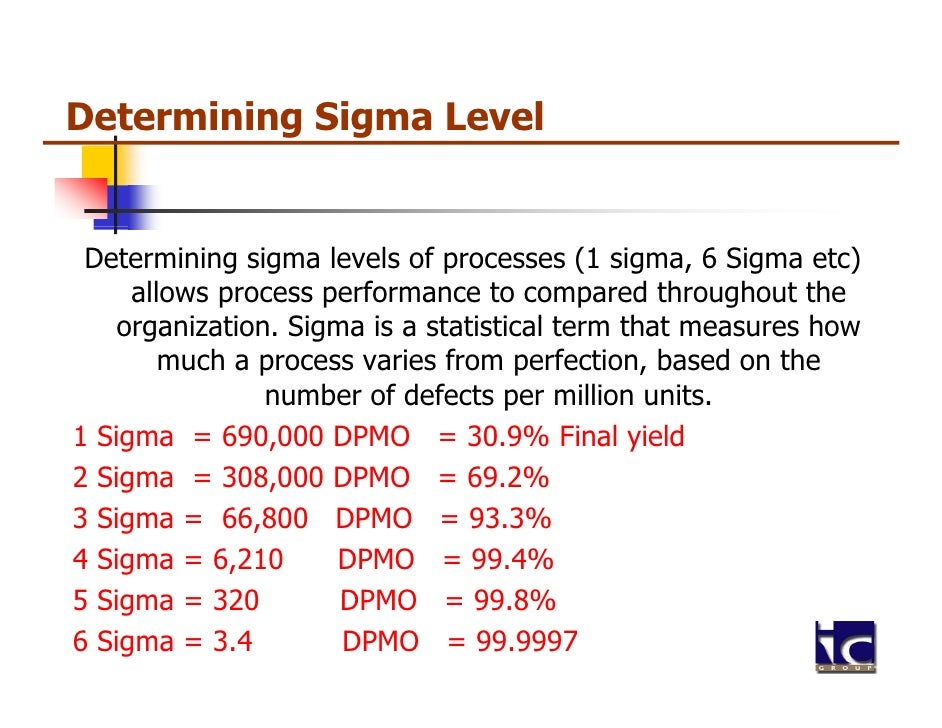

Six Sigma is a process that requires thorough knowledge and understanding of various processes and methodologies. Verify – Testing and validation of any deliverables.Optimize – Identifies abilities to deliver and maximize design elements.Design – Develops processes to meet customer’s expectations.Identify – Identifies customer and project specifics.V – Verify – Confirms the ability to meet customer’s requirementsģ) DFSS – Used for developing or redesigning a net new product or service.D – Design – Develops a process to meet customers’ needs.A – Analyze – Identifies the process that meets customer’s expectations.M – Measure – Provides a measure of customer’s needs.D – Define – Identifies problems or goals that need attention.C – Control – Implements and maintains improvements for sustainabilityĢ) DMADV – Used for new processes, products, or services.I – Improve – Finds solutions to address problems.A – Analyze: Identifies the root causes of any deficiencies and opportunities.M – Measure – Provides a measure of the problem or process.D – Define – Identifies problems/objectives that need attention.Maximizes & stabilizes business processes and designs Now that you know the basic working of Six Sigma, let’s dive into the two primary methodologies:ġ) DMAIC – Used for existing processes. The organization must involve its employees with well-defined roles, responsibilities, and objectives. This will help to identify the gaps in the processes and the work needed to be improved.ģ) Employee – Without decent leadership, Six Sigma implementation is very difficult. Since the customer defines a business’s growth, quality needs to be in check from their perspective. They also mold the delivery, performance, service statistics.Ģ) Process – Defining processes and corresponding metrics is the key aspect of Six Sigma. They are the key for any business and are always on (should be!) top priority. The table goes as follow: Sigma Levelġ) Customers – Customers are the market king. There are multiple Sigma levels where each of them indicates the number of allowed defects per million and thus the level of process maturity. The process produces 3.4 defects per million opportunities (DPMO).

A process that performs at a 6 sigma level free#

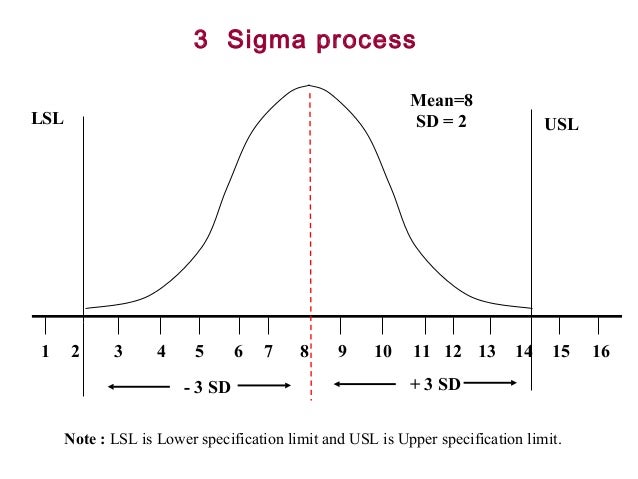

A perfectly carried out Six Sigma process produces 99.99966% of opportunities free of defects. It is used to remember the percentage of values that lie within a bandwidth around a normal distribution with a width of 1σ, 2σ, and 3σ respectively. The 68-95-99.7 Rule mentioned above in the diagram is known as an Empirical rule. In other words, there is very little deviation from the standard and is within the tolerance zone. Anything that is between +/- 6s from the centerline of a control chart is considered to be well controlled. A “SIGMA” is a measurement of standard deviation (often abbreviated as “s” or “σ”). The term Six Sigma is derived from the statistical process modeling in manufacturing. To get a detailed insight on Six Sigma head towards our blog The Six Sigma Process It’s a continuous improvement process, with a focus on: Six Sigma is a collection of quality-control tools that businesses can use to eliminate defects and improve processes in order to increase profits.Ī Six Sigma processes 99.99966% of all opportunities to produce some feature of a part that are statistically expected to be free from defects. Introduced and refined in the manufacturing department of Motorola in 1986 by an American engineer Bill Smith, Six Sigma seeks to improve manufacturing quality by identifying and removing the causes of defects and minimizing variability in manufacturing and business processes. Being in the market for the past 35-40ish years, Lean Six Sigma has proven to be a foolproof methodology to reduce errors and increase productivity. One of the most significant and stand-out methodologies - Six Sigma, has found itself to be a very effective module.

Their quest is still operational today as theories and methods for improvements are posited, reviewed, tested, and implemented. This quest was charted by individuals like Walter Shewhart (The Grandfather of Total Quality Management), Kaoru Ishikawa, Frederick Taylor, Shigeo Shingo, and many others. Lean Six Sigma Online Certification & Trainingįor more than a century, the industrial world has seen great efficiency and growth in production of higher quality.Six Sigma Virtual Instructor-led Training.Six Sigma Master Black Belt Certification and Training.

0 kommentar(er)

0 kommentar(er)